Download more information on the NAI PRO-X110 Electronics X-Ray Inspection System to learn about key features and product specifications.

NDT X-Ray Inspection Imaging

The Next Generation in Non-Destructive X-Ray Inspection Imaging

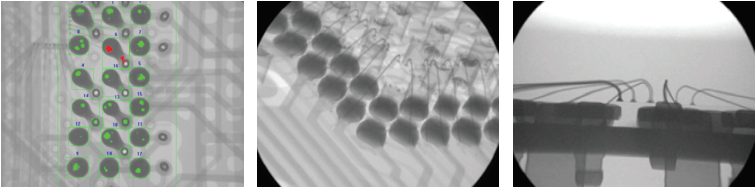

Safe, simple, and smart. Protect your product and brand with NAI’s new X-ray inspection machine. Simple to use with intuitive software and controls, the PRO-X110 is ideal for a wide range of detection applications. Schedule an application analysis to learn more about the benefits for your bottom line.

- Compact/mobile design, easy to move

- Ergonomic and intuitive design – simple operation

- Built NAI tough! Longest warranty in the industry

- Unsurpassed performance at a competitive price

- Customize your cabinetry with your logo and brand design

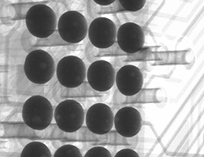

See the Smallest of Details

NAI’s PRO-X110 X-Ray Inspection Machine has outstanding image quality down to the smallest detail – perfect for all electronics applications. The PRO-X110 offers magnification up to 400X with plenty of tube power to penetrate the most difficult product.

PRO-X110 Key Features

Ergonomics

Compact machine designed to be operated by any size operator. Adjustable operator’s workstation to accommodate all heights.

X-Ray Tube Design

Wide beam sealed tube (no maintenance) which is excellent for angle viewing of the sample. No tilt of the sample is necessary.

X-Ray Tube Specifications

High kV (110kV). High power (20 watt). Small focal spot (5 micron). Short FOD (7mm). A combination of specs that address all of the SMT inspection requirements.

Detector

Digital extreme high-resolution FPD for balanced, high-magnification imaging. Arc motion for all angle viewing. No tilt of the sample necessary.

Sample Load/Unload

Sliding door for easy access to sample area. Sample Table 0-180 degree rotating table to effectively generate multiple viewing positions.

Sample Table

0-180 degree rotating table to effectively generate multiple viewing positions.

Image Programming

Pro-X Auto Image Creation. Create image libraries by clicking just one button. Saves kV, mA, magnification settings, X/Y position and tilt angle.

Service/Maintenance

Open internal design for easy access to ALL critical areas of the machine.

Mobile

The machine is small and mobile. Easy to move from location to location.

Price/Performance

Less than $80,000 for a high-powered, high-performance X-ray solution.

Contact Us Today

Contact Us to Discuss Your Non-Destructive X-Ray Imaging Needs or to Place an Order

Schedule an application analysis to learn more about the benefits for your bottomline.

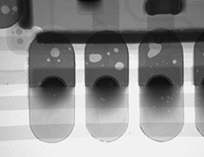

Image Processing Software

Vital to quality control, NAI software allows manufacturers to find contamination, scratches, cracks, blemishes, gaps, pits and other production flaws. Post-processing software can detect defects invisible to the human eye – faster and more accurately.

We offer several user-friendly software packages to meet a variety of applications for a wide range of industries. Choose from one of our three software packages or let us put together a customized package to fit your unique needs.

Standard Software

- Image capturing and saving (.jpg, .bmp, .tif)

- Auto Live image averaging

- Post capture image enhancements:

- Brightness and contrast adjustments

- Image filters (sharpen, pseudo color, negative)

- Point-to-point distance measurement tool

- Measurement calibration (inches, mm, mils)

- Image annotation tool:

- On-screen text tool

- Arrow drawing

- Line, circular or rectangular shape drawing

- Quad view imaging tool

(allows user to capture four

images and combine them

into one picture)

Optimum Software

- All features from the Standard Software

- BGA measurement algorithm tools

- Solder ball size:

- Ball area

- Ball diameter

- Ball roundness

- Percent voice

- Pass fail criteria

- Image reporting

Advanced Software

- All features from the Standard and Optimum

- QFN measurement algorithm tools:

- Joint area

- Percent void

- Pass/fail criteria

- Semiconductor measurement algorithm tools:

- Bond wire sweep

- Die attach void measurement

- Pass/fail criteria

- Gull wing joint measurement algorithm tools:

- Joint area

- Percent void

- Pass/fail criteria

- Drill offset measurement

- Center to center offset(X & Y distance)

Contact Us Today

Contact Us to Discuss Your Non-Destructive X-Ray Imaging Needs or to Place an Order

Schedule an application analysis to learn more about the benefits for your bottomline.